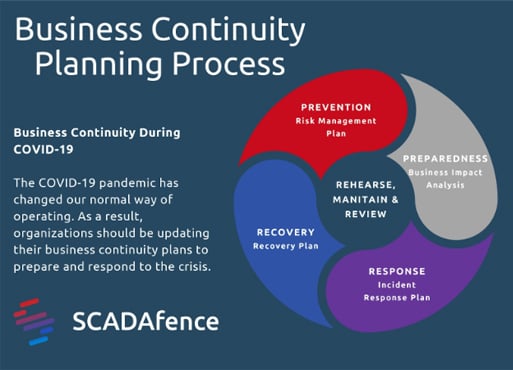

Business continuity planning (BCP) is the process involved in the creation of a system that prevents potential threats to a company, and also aids in its recovery.

This plan outlines how assets and personnel will be protected during the current COVID-19 crisis and how the business can function normally throughout the crisis.

This business continuity plan includes contingencies for human resources, assets, business processes, and any other aspects that could be affected by downtime or failure.

Common Threats To Production

One of the most common threats on manufacturers is a breakdown of production equipment. That is why manufacturers invest heavily in human capital, hiring skilled engineers and other specialists who can rapidly make repairs when needed.

However, manufacturers should be investing just as wisely in protection against other threats that are as destructive: Malware, viral diseases, natural disasters, fire & smoke, flooding, utility outages and IT disruptions.

In addition, during the COVID-19 crisis, there’s a lot more remote work and more things are done quickly, rather than with long term planning. This can create security and operational risks.

SCADAfence can help you be in control.

You need to know about all remote sessions, what your industrial workers are doing, and how your facilities are functioning. Also since you cannot send people physically on site due to quarantines, or there’s limited availability of personnel, you need to do things remotely and they must be automated.

Business Continuity Planning With SCADAfence

Below are the key areas in which SCADAfence comes into play in ensuring your company’s business and production continuity.

Understanding Your Risks

Continuous assessment and visualizations of the risks to your OT network is an essential part of your organization’s preparedness to transition into business continuity (BC) mode.

SCADAfence Helps Organizations Understand Their Risks By:

- Identifying key/critical assets.

- Assessing the risks to the crown jewels.

- Continuous dependencies visibility and a snapshot of the network.

- Ensuring backups and remote access security.

- Ensuring that all employees could sustain production.

- Getting visibility using network maps, remote access and user activity tracking.

Early Detection of Attacks & Vulnerabilities

Over the last few years, the manufacturing industry was hit hard by ransomware attacks. Leading organizations such as Boeing, Nissan, Mondelez and Renault, are just a few of the high-profile producers that have been derailed by infections. Early detection of malware, can significantly lower (and prevent) the impact of a cyber attack using our manufacturing OT security solution.

SCADAfence Helps Organizations Detect Attacks With:

- Exposure analysis.

- CVE management.

- Central governance & compliance.

- Insecure protocols & access.

- Real-time malware detection.

- Continuous reduction of the attack surface.

Asset Management & Identification of Critical Assets

During the prevention and preparedness stages, continuously mapping your assets and identifying the critical assets in your production process is the key to securing them. However, possibly more important during the response and recovery stages is to quickly identify missing critical assets or inconsistencies in the network’s design and performance. In addition, the ability to compare between primary and secondary sites (as part of responding to a crisis) is crucial.

SCADAfence Helps Organizations With Asset Management By:

- Maintaining a detailed and updated asset inventory at all times - both in primary and in disaster recovery (DR) sites.

- Managing OT assets down to the model and firmware level, and tracking asset status, owner and location.

- Identifying key/critical assets.

- Creating check points of asset inventory statuses.

- Alerting on any deviation from the asset inventory - including missing, new and malfunctioning devices.

Incident Response

Early detection and rapid response based on predefined playbooks are key to responding to business continuity incidents.

SCADAfence has you covered by covering both your operational and security aspects. While providing early detection of potential production interruptions, we ensure continuous production work, including remote access, user activity tracking, permitting access to your 3rd party vendors and supply chain, without the additional risks of increased attack vectors.

SCADAfence Helps Organizations Respond To Incidents With:

- The detection and alerting of cyber security and operational incidents.

- Overseeing DR site operations - and comparing them to the approved production status.

- Asset management of their primary and secondary sites.

- Multi-site management.

- Integrating with their existing SIEM SoC systems.

- Full-fledged ticketing and a workflow of current issues.

Recovery

After the COVID-19 situation (or any other crisis for the matter) is over and business is returning to normal operations, companies should strive to return to business as usual as quickly as possible. Having an understanding of what business “looked” like before the crisis, tremendously helps in getting back to business as usual. This Includes risk assessment reports and compliance reports to ensure that the production system is up and running correctly and is compliant with the industry and the organization’s standards.

SCADAfence Helps Organizations Recover By:

- Recording “approved” asset inventory status & network state for confirmation of “return-to-normal” state.

- Network traffic activity dashboards.

- Security & network risk assessment reports to make sure the network is secure.

- Standard and policy compliance reports

WITH SCADAFENCE, YOU CAN ENSURE CONTINUOUS PRODUCTION WORK!

Get OT Security as a Managed Service - Click here for more details.

Get OT Remote Access Security - Click here for more details.